I feel your pain on cleaning up all that shattered glass.

Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Today I worked on......

- Thread starter kevlar

- Start date

Sure, glass everywhere, the little shards were the worst..I feel your pain on cleaning up all that shattered glass.

Never seen that before, you’ve done a great jobAt last I finished stripping and re assembling my WH20 after the glass shattered.

Who would believe it, I am not o do. Stripped my CV over 11 years ago and just putting it back together. Crazy.

Reminds me of my Addams.... took just over 10 years and 2 house moves

Reminds me of my Addams.... took just over 10 years and 2 house moves Looks a nice original playfield, probably the best looking pin ever! Get it doneWho would believe it, I am not sure i do. Stripped my CV over 11 years ago and just putting it back together. Crazy.

You must be buzzing tonight GonzoLooks stunning mate

- Joined

- Oct 15, 2013

- Messages

- 102

I have no interest in toppers, and in any event I don't have height clearance to fit one on top of my JP2.

So I have made a topper.

I started with this, which I bought from someone here:

and made this:

Features are:

Flickering flames on gate

Jeep with working headlights and interior light

Flashing red lights on 'electric' fence

30+ individually addressable rgb leds uplighting the scene, controlled by Wled via phone app. Can be set to a myriad of colours and animations

Interactive floodlights triggered by in-game signal. Currently wired to sync with flasher on T-rex ramp.

Switches on and off with game.

Powered from 12v supply, not from game or lamps.

Uses Feed Frenzy board for power & led yumminess and LollyGI for game trigger sync. Also separate 240v > 12v power supply.

So I had to sling it on a piece of wood in front of the backbox with cardboard behind. Classy.

Not that you'd want to, but to show it is RGB...

Here are a couple of very poor videos. They don't show the sync'd floodlights very well as it's in music mode, so just cycling through attract mode lighting - a bit on-off-on-off. More effective during gameplay.

THANK YOU so much to @MadNat and @stumblor for all their help.

God knows what I'll do with it now! It's been a fun project.

It's been a fun project.

So I have made a topper.

I started with this, which I bought from someone here:

and made this:

Features are:

Flickering flames on gate

Jeep with working headlights and interior light

Flashing red lights on 'electric' fence

30+ individually addressable rgb leds uplighting the scene, controlled by Wled via phone app. Can be set to a myriad of colours and animations

Interactive floodlights triggered by in-game signal. Currently wired to sync with flasher on T-rex ramp.

Switches on and off with game.

Powered from 12v supply, not from game or lamps.

Uses Feed Frenzy board for power & led yumminess and LollyGI for game trigger sync. Also separate 240v > 12v power supply.

So I had to sling it on a piece of wood in front of the backbox with cardboard behind. Classy.

Not that you'd want to, but to show it is RGB...

Here are a couple of very poor videos. They don't show the sync'd floodlights very well as it's in music mode, so just cycling through attract mode lighting - a bit on-off-on-off. More effective during gameplay.

THANK YOU so much to @MadNat and @stumblor for all their help.

God knows what I'll do with it now!

Attachments

Nice work Tom! And nice to see my old machine getting some love.

D

Deleted member 2463

you need a new QR code LOL

Obviously you never tried those pics @Neil McRae as no matter how much I did it wouldn’t log in.you need a new QR code LOL

How’re feel free to do some of my hard challenges if you do

Got my AIQ all set up

Big thanks to @philpalmer, @CHRIS B PINBALLS and @Colywobbles for making this happen!

Big thanks to @philpalmer, @CHRIS B PINBALLS and @Colywobbles for making this happen!

Attachments

I've been messing with a 2nd hand and very used chinese laser for a while now. Whilst it has been a joy to learn how to use, its slow, has a slighlty unlevel bed and can be time consuming to use effectively. After i fried my pinky finger for the umpteenth time in the beam of the chinese laser (theres no safety in this one) adjusting the beam i thought it best to upgrade so i can continue my laser obsession without losing more skin.

Chinese 50w one in the back, new Boxford 80w at the front:

I naturally did a bunch of pinball stuff. Some coin door logos, apron decals, shooter rod decals etc. I'm currently re-doing some stuff for my Tron that i first did with the chinese laser i wasn't quite happy with:

Oh, i did an Elvira chopping board too:

Chinese 50w one in the back, new Boxford 80w at the front:

I naturally did a bunch of pinball stuff. Some coin door logos, apron decals, shooter rod decals etc. I'm currently re-doing some stuff for my Tron that i first did with the chinese laser i wasn't quite happy with:

Oh, i did an Elvira chopping board too:

Nice.

Yep it’s a great hobby and as you say very time consuming, I actually started with a little 300x200 one although a HPC not Chinese as I used a mates before buying my 1st one that was an absolute fire hazard and and dangerous to even operate.

I never us mine without the hood down ever! as it doesn’t warn you of impending doom but will just take your eyesight away. How you finding the Boxford? I looked into them but Bertha came up just at the right time and I’ve never looked back.

If I can help in anyway just shout but it does look like you have it sussed anyway.

Yep it’s a great hobby and as you say very time consuming, I actually started with a little 300x200 one although a HPC not Chinese as I used a mates before buying my 1st one that was an absolute fire hazard and and dangerous to even operate.

I never us mine without the hood down ever! as it doesn’t warn you of impending doom but will just take your eyesight away. How you finding the Boxford? I looked into them but Bertha came up just at the right time and I’ve never looked back.

If I can help in anyway just shout but it does look like you have it sussed anyway.

Thanx for the offer Col, i may just do that one day. The only real issue i have is knowing what Kerf to set for some different plastics (eg: extruded acrylic vs cast gives me different kerf settings and not all plastic is the same as im sure you know). This will almost always result in waste as you figure it out but i usually just make a couple of little squares on a piece of new material and from that i know where i am. I've made kerf gauges for some material i use often but once i know, i just save the details in the cut library.Nice.

Yep it’s a great hobby and as you say very time consuming, I actually started with a little 300x200 one although a HPC not Chinese as I used a mates before buying my 1st one that was an absolute fire hazard and and dangerous to even operate.

I never us mine without the hood down ever! as it doesn’t warn you of impending doom but will just take your eyesight away. How you finding the Boxford? I looked into them but Bertha came up just at the right time and I’ve never looked back.

If I can help in anyway just shout but it does look like you have it sussed anyway.

I learned how to use Inkscape and RDworks when using the chinese laser. Now using Lightburn as its so much easier. That said, there are some things that lightburn can't do, that Inkscape can and vice versa so i still use them both. Node editing, tiled clones for borders, text and image manipulation are all best done with Inkscape i find, as lightburn can sometime get confused with intricate node paths which results in lightburn thinking theres a bunch of open shapes. Converting Inkscape files into .dxf, then importing into RDworks always gives me perfect closed paths. That said, image tracing and dynamic bordering i find far easier to do in lightburn.

The Boxford machine is of course a million miles ahead of the chinese one, but even that needed quite a bit of fiddling to get perfect. It wasnt quite perfect on raster and vector cuts together so needed belts tightening and beam aligning at first but now seems to be working fine. The chinese one i have is pretty decent, i fitted a new tube and power supply about a year ago and its been great since. It does need a lot of fiddling to get the jobs right though mostly due to the need to check beam alignment and bed level before every single job. A simple set of apron decals took a very,very long time to do on that machine as it was best ran at slower speeds with the 1inch lens i was using. The boxford came with a 9mm lens which is ok but i have several other focal length lenses to try. I've only used the 2" one for finer detail and cutting but went back to 9mm as i found the 2" didn't like the faster engraving speeds. Boxford BGL690 is rated at 80/100w and has a 900x600 bed size, auto focus, onboard chiller/heater and of course has all the safety lockouts. Chinese one is basically a death machine waiting to blind you, or just burn little holes in your hands. Its bed size is 500x300 and Its internal wiring needed redoing to make it safe(ish) but it has no safety lockouts so when aligning the beam, its very easy to leave your hand in the invisible beam path when pulsing the laser, resulting in a very painful 5mm hole in your skin. I have a set of laser proof goggles so i used those with the hood up but you cant do that with the Boxford as it has magnetic switches on all the doors.Thankfully.

You mentioned your machine, Bertha? Who makes that? I did look at a load of machines but found the Boxford was best value for the size. I could have bought a huge machine from china for half the cost (even with VAT and delivery) but lead time was ridiculous and there is no customer support for parts. I eventually went with a UK supplier because they are close to where i live and i can go see them in person if i need to. That meant paying twice the price, but peace of mind means a lot.

I will of course be doing a load more pinball stuff for my machines when i get round to it, but in learning how to use these machines i've wrecked a ton of materials. Plastics, mdf, expensive hardwoods, leather and a lot of dinner plates, all toast. RIP. lol. Some other stuff i've done:

Godzilla playing pinball plate:

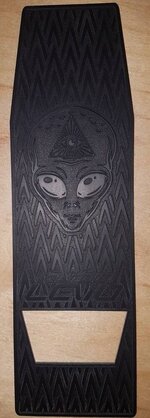

Rubber bash guard for a friends Specialized Levo bike (guess what he's into? lol)

Next up is an acrylic gaming chair i always wanted to hurt my back on. So once xmas is over and im done with doing trinkets for family i'll be getting on with that. Oh and a battery holder for my electric bike build.

Maybe a fiber laser next? Going to get one eventually but the costs spiral massively for the silly type of hobby stuff i want it for. Might have to go chinese on that one just to see. *slaps forehead*

Of course, I offer my help if ever needed to you too, Col. And anyone else reading should they need it. Always great to learn new stuff.

I love the smell of burning acrylic in the morning.....

Another? How many is that now then?Tried to fix AIQ, looks like another node board failure

Probably around 4/5 now over various machinesAnother? How many is that now then?

Had it always been confirmed that the node boards the fault? That’s bad luck really.Probably around 4/5 now over various machines

Tried to fix AIQ, looks like another node board failure

Great news and support from Phil @ PH, new node board due today

Edit, now arrived !!

Last edited:

Doggard

Registered

Not really pinball related, but today I’m finishing off my model space, R2D2 parts build . Only 2 issues left, fingers crossed he works at the end. It’s been a long 3 years