No worriesNot sussed those ones out yet, there's a bit of a long queue here -- been prioritising those that aren't mine

Well one of them probably doesn't have a fault I think it was the actual pins on the connector block, be interesting to know, (dont worry I don't care if it works fine

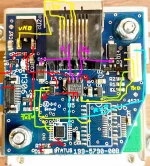

The other acting as node 9 is definitely a cap issue not holding its charge to start the board I suspect, as it will work once machine on for a bit and a charge has been put through the cap, quick turn off and on again works perfect, until powered off for a bit.