A week in and the Bambu is even more impressive than first impressions.

The 'issue' with noise and vibration is easily fixed by running it in 'silent' mode, which is 50% speed. It's not obviously not silent but it is very quiet, even at 50% speed it is quicker than the flashforge. I haven't yet had the guts to try it in 'ludicrous' mode, which is 200% speed, but will give it a go at some point.

What is a nice touch is that you can change this speed from your phone (or the machine) at any point during the print, so when I've had a long print I start it off on normal and when it gets late I run it on silent over night.

The adhesion to the bed is so finely tuned to be unbelievable. At the start of each print it goes through an autobed levelling sequence which takes a few minutes (I'm sure you can turn this off in settings, but I'm not in that much of a rush for my prints anyway). This means that every single print is perfect. More surprising is that once the print is finished and cooled down the model isn't stuck to the bed at all, it's as if elves have placed the finished model in the cabinet, rather than it having been printed in there having been stuck to the bed at some point.

I've done a few multicolour prints of varying types.

Firstly a simple switch colours at a particular layer height, this has minimal wastage (only the purge tower really) and adhesion between different filaments is perfect.

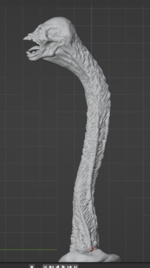

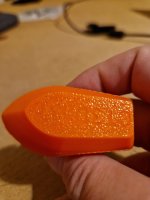

Secondly I did a print of a 'zombie carrot' I'd found.

There were a couple of issues. One of my own making, the poop chute for the purged filament was blocked which meant the extruder head couldn't get back to position. The machine spotted this and simply paused the print until it was cleared. The second is the amount of wasted filament between colour changes was huge. The fact that it prints each colour per layer means that it can change filament up to 3 times per layer, each change only wastes a little, but it soon adds up. (I found a multicolour benchy to torture test the colour changing to really demonstrate this!)

Thirdly I printed one of my bolt carriers with writing in a different colour. This was by far the most impressive. The definition of the type, the 'join' of the 2 colours, the smoothness is absolutely outstanding. If I hadn't printed it myself I wouldn't have believed it could have been printed this way - it looks like the type has been ink stamped on it's that good.

What was also impressive is the information on the Bambu Lab Wiki

The Bambu Lab Wiki is a collection of helpful articles and guides dedicated to our Hardware and Software products

wiki.bambulab.com

It has everything there you could possibly need, from specific hardware issues with each of the printers with easy to follow step by step instructions to how to dissemble and reassemble components, to correcting issues with printing - it is well worth taking a look - even if you don't own a Bambu - as it has generic solutions to print problems and the causes of them.

I'll put a different post up about the AMS, but that is also a fantastic piece of kit.