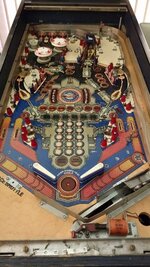

Im confused. How can adding a resistor make LED's not flicker?? Thats usually done by a rectifier or capacitor (or combination of the two)... Surely all a resistor will allow you to do is to bring down the operating voltage if it's a little hot...I've just LED'd the playfield inserts on my Xenon. On the whole I'm pro LED but I don't usually see the need on older machines. However the inserts on the CPR playfield I fitted to this machine are really see through, you can clearly see all the bulbs through them which leads to all the colours being very pale. Anyway, I thought I'd try colour matching the inserts with comet LED's after buying and fitting the Siegecraft classic stern/bally LED adapters. Without these adapters LED's flicker like crazy on these old machines, from what I understand using these is basically the same as soldering a resistor to every lamp holder, just much easier. I'm very happy with the result ( probably annoyed @DRD though)

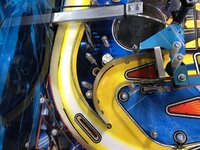

View attachment 68824

Just wondered