My $0.02 (and no - I am NOT bashing Stern or anyone, just tipping my thoughts into the discussion).

The MP24943 is a switching regulator that is specified to deliver 3A output with a MAXIMUM recommended input voltage of 55V.

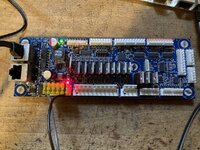

AFAIK, this node board derives its supply from the 48V switching power supply which is then fed to the input pin of this chip as well as many other places.

Pin 1 of this chip is the voltage input pin - this seems to be where the blammo (technical term) happens on a few of these I have seen.

My electronics experience tells me do not EVER rely on a small margin of safety when designing things. This device is being supplied with an input voltage that is only a small margin above its suggested MAXIMUM operating condition. 48 VS 55 is FAR too close for my liking and I would NEVER, EVER design such a thing.

In practice, my thoughts are proving correct. This device is simply running way too close to its maximum operating conditions and we are going to see many, many more failures just like this.

Fortunately, this device is cheap and common and replacing it should be a fairly easy task for a competent technician. Forget field repairs but a bench repair on this problem should be easy to effect and simple enough to test once done.

I think this is a classic case of a "fresh from uni" engineer with little, to no, real world experience designing this product. They are usually great on theory and dumbfounded when things like this happen to their designs. Clarifying again that this is just my opinion - and after all, what would I know?

The MP24943 is a switching regulator that is specified to deliver 3A output with a MAXIMUM recommended input voltage of 55V.

AFAIK, this node board derives its supply from the 48V switching power supply which is then fed to the input pin of this chip as well as many other places.

Pin 1 of this chip is the voltage input pin - this seems to be where the blammo (technical term) happens on a few of these I have seen.

My electronics experience tells me do not EVER rely on a small margin of safety when designing things. This device is being supplied with an input voltage that is only a small margin above its suggested MAXIMUM operating condition. 48 VS 55 is FAR too close for my liking and I would NEVER, EVER design such a thing.

In practice, my thoughts are proving correct. This device is simply running way too close to its maximum operating conditions and we are going to see many, many more failures just like this.

Fortunately, this device is cheap and common and replacing it should be a fairly easy task for a competent technician. Forget field repairs but a bench repair on this problem should be easy to effect and simple enough to test once done.

I think this is a classic case of a "fresh from uni" engineer with little, to no, real world experience designing this product. They are usually great on theory and dumbfounded when things like this happen to their designs. Clarifying again that this is just my opinion - and after all, what would I know?