Pinball info

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New (Redesigned) Boards

- Thread starter Paul

- Start date

- Status

- Not open for further replies.

How about producing sound cards with improved components, amps etc..

Conservatively, around 9-10 hours build time. Takes around 30 mins to test every single solenoid. Testing is something that as far as i am concerned will always happen - nothing will ever leave here without being fully tested, either in a machine or on a test fixture (if 11B then it will be physically tested in a machine before despatch).Fantastic! How many hours spent on that one board inc testing

How about producing sound cards with improved components, amps etc..

Deffo doable. I dont build anything using unknown sourced components, and always look to known brands where i can. Example is the JJP Capacitors. I can get cheaper ones, but i wont since it compromises quality - the ones i replace with are better than the originals.

Sometimes though you have no option since parts just arent available. However in the case of the Sys11 boards as an example, 99% of components are sourced from reputable suppliers (Mouser/Digikey/RS etc). When it comes to things like PIA's and 6802 processers your options are somewhat limited, so i will take what i can get, however in those cases everything is tested before using it (the 6802's and 6821's I used were all tested prior to use - just as well since i bought a number of PIA's and two were faulty!).

With regards to older Audio boards (WPC89 for example) it would be a waste to upgrade caps to say audio grade Nichicon, since the source material isnt good enough quality to warrant the extra cost. Saying that though, it doesnt mean that you can use cheap rubbish though.

Pinsound have the market sown up with respect to audio upgrades though...

Unfortunately pinsound boards are only compatible with a couple of system 11 pins.. we upgrade these machines with the best LED’s and speakers however the sound boards are average at best. I think there is a market for producing the best quality sound using original roms..

Crewey

Site Supporter

Yah Pinsound have been saying for a long time support would be coming for many games, early DE (Robocop) and also certain SAM games such as Family Guy which has an awesome audio package but the fidelity sucks. David Thiel has discussed the poor audio quality issues of this era Stern in interviews.Unfortunately pinsound boards are only compatible with a couple of system 11 pins.. we upgrade these machines with the best LED’s and speakers however the sound boards are average at best. I think there is a market for producing the best quality sound using original roms..

@Paul

What is redesigned about the sys11 board out of interest bud

The board is not a redesign per-say but predominantly a reproduction (My bad). The Rottendog boards are a redesign in that all the drive circuits use MOSFETs and have a complete different logic for incorporating blanking.

These boards are essentially a reproduction with some modifications and (what I consider) improvements.

- The daughter boards implement successive features that Williams REMOVED during the life cycle of the board (11 -> 11A -> 11B -> 11C).

- The sound/speech section is split between digital and analog. The digital section is on the main board. The analog section is on the daughter board. The daughterboard is only needed for 11/11A/11B.

- The amplifier is on a daughter board and only needed for Sys11.

- The digit display is on a daughter board and only needed for Sys11.

- The OST (OSL daughter board) is a chargeable added feature. See here for a demo of this (This is a stand alone version demonstrated - which i will also make available - however it is a piggyback board option on Victor's Sys11 Boards) :

- The OEM board uses SRC (resistor and capacitor networks). These are no longer available. Instead this board uses resistor networks and discrete capacitors.

- The solenoid drive circuits are identical to the OEM circuit.

- The switch matrix circuits are identical to the OEM circuit.

- The lamp row drive is identical to the OEM circuit. The lamp column drive can be identical but also supports the use of MOSFETs to remove the heat dissipating 27 Ohm @ 5W resistors (This is the option i build these with). It's possible to use a TIP107 (instead of a TIP42) to reduce the current required into the base but a MOSFET is just a better solution to reduce the heat dissipation.

- There is an LED indicating 18V (lamp matrix) power.

- There are LEDs indicating the coin door (MEMPROT) state and the flipper ground relay enable state.

- The display drive circuits are identical with ONE exception. The OEM circuit uses a 74154 4:16 decoder. This IC is a DIPW-24 and no longer available as DIPW-24. It is however available as SOIC-24 and using that would require a small adapter board. If you look at the RD MPU9211 you will see that it uses such an adapter. The SMT IC is mounted on the other side of the board which is why you can't see the IC. The circuit was changed to use 2x 74138 3:8 decoders cascaded together to produce the same 4:16 decoder result. The 74HCT138 (or 74LS138) is readily available as DIPN-16.

The way this works is that the base board will work as-is on a Sys11C system. System 11B needs an added piggyback DAC. System 11A also needs an added piggyback DAC (configuted diffrerently to the Sys11B one). System 11 needs the same DAC as the Sys11a, but also a Diagnostic Digit Display daughter board and a CPU Amplifier TDA2002 daughter board). The OSL piggyback is available as a chargeable add-on piggyback board.

As i've said before these will be custom built to requirements, and therefore have a leadtime of 2-3 weeks, however they are using through hole and are generally regarded in the USA as superior replacements to the RD boards. As a clue, Victor has a waiting list tens long just for these, let alone other boards. they will also be fully tested - either on my system 11 test rig or in the case of Sys11B in a real machine.

I may of missed it in your system 11 explanations, Victor mentioned an extra for the special solenoids particularly on Big Guns. "Big Guns uses the special solenoid playfield switches and there are two options that help with potential problems related to this" do you know what he means about this @Paul ?

Last edited:

I asked Victor directly, since that makes more sense. here is his reply....I may of missed it in your system 11 explanations, Victor mentioned an extra for the special solenoids particularly on Big Guns. "Big Guns uses the special solenoid playfield switches and there are two options that help with potential problems related to this" do you know what he means about this @Paul ?

Special solenoids are not specific to Big Guns. All WMS3-9 and early WMS11 machines have special solenoids. This part of the system is problematic. A lot of boards got destroyed from locked on SST/SSD problems. That's what the One Shot Trigger board is for. It's designed to prevent these kinds of failures causing board damage.

--

The fuse board is a hardware solution. The OST is a software solution. Watch the videos. If that doesn't convince you then nothing will.

I will be selling the one shot Trigger board (the one in the second video) if anyone is interested, once the boards arrive.... few weeks probably. I Believe that this will work on the original boards to protect those.

I'll only be announcing boards available once i have them in my hands. But i do have a decent amount coming. The art (and what i will probably get wrong) is the quantities required. This will come over a few months.

Last edited:

PinIB

Site Supporter

Same for me (Whirlwind). This is great stuff.

On the replacement Sys11 boards the oneshot is available as a piggyback board as shown above circled in Blue. As per the video, it is also available as an add-on which connects to the inputs and outputs...

(Two different - One using KK connectors, the other using Modular RJ45). Both will work for Real machines - probably easier to use the modular ones as it makes things tidier

Last edited:

Massive consignment of boards have arrived. Please give me a few days to sort them and will get an update out!

The board is not a redesign per-say but predominantly a reproduction (My bad). The Rottendog boards are a redesign in that all the drive circuits use MOSFETs and have a complete different logic for incorporating blanking.

These boards are essentially a reproduction with some modifications and (what I consider) improvements.

- The daughter boards implement successive features that Williams REMOVED during the life cycle of the board (11 -> 11A -> 11B -> 11C).

- The sound/speech section is split between digital and analog. The digital section is on the main board. The analog section is on the daughter board. The daughterboard is only needed for 11/11A/11B.

- The amplifier is on a daughter board and only needed for Sys11.

- The digit display is on a daughter board and only needed for Sys11.

- The OST (OSL daughter board) is a chargeable added feature. See here for a demo of this (This is a stand alone version demonstrated - which i will also make available - however it is a piggyback board option on Victor's Sys11 Boards) :

- The OEM board uses SRC (resistor and capacitor networks). These are no longer available. Instead this board uses resistor networks and discrete capacitors.

- The solenoid drive circuits are identical to the OEM circuit.

- The switch matrix circuits are identical to the OEM circuit.

- The lamp row drive is identical to the OEM circuit. The lamp column drive can be identical but also supports the use of MOSFETs to remove the heat dissipating 27 Ohm @ 5W resistors (This is the option i build these with). It's possible to use a TIP107 (instead of a TIP42) to reduce the current required into the base but a MOSFET is just a better solution to reduce the heat dissipation.

- There is an LED indicating 18V (lamp matrix) power.

- There are LEDs indicating the coin door (MEMPROT) state and the flipper ground relay enable state.

- The display drive circuits are identical with ONE exception. The OEM circuit uses a 74154 4:16 decoder. This IC is a DIPW-24 and no longer available as DIPW-24. It is however available as SOIC-24 and using that would require a small adapter board. If you look at the RD MPU9211 you will see that it uses such an adapter. The SMT IC is mounted on the other side of the board which is why you can't see the IC. The circuit was changed to use 2x 74138 3:8 decoders cascaded together to produce the same 4:16 decoder result. The 74HCT138 (or 74LS138) is readily available as DIPN-16.

The way this works is that the base board will work as-is on a Sys11C system. System 11B needs an added piggyback DAC. System 11A also needs an added piggyback DAC (configuted diffrerently to the Sys11B one). System 11 needs the same DAC as the Sys11a, but also a Diagnostic Digit Display daughter board and a CPU Amplifier TDA2002 daughter board). The OSL piggyback is available as a chargeable add-on piggyback board.

As i've said before these will be custom built to requirements, and therefore have a leadtime of 2-3 weeks, however they are using through hole and are generally regarded in the USA as superior replacements to the RD boards. As a clue, Victor has a waiting list tens long just for these, let alone other boards. they will also be fully tested - either on my system 11 test rig or in the case of Sys11B in a real machine.

View attachment 250656

On the replacement Sys11 boards the oneshot is available as a piggyback board as shown above circled in Blue. As per the video, it is also available as an add-on which connects to the inputs and outputs...

View attachment 250658

(Two different - One using KK connectors, the other using Modular RJ45). Both will work for Real machines - probably easier to use the modular ones as it makes things tidier

One of the problems with copying an original system 11 design is you build in all the issues. I can see some changes, but it looks like they are using the original driver logic, which will burn just like an original if there is a fault. and take out the transistors and 74 logic! Why not use mosfet designs here that are well tested these days.

Also paul, are you assembling these yourself or getting a company to do it? I hope the latter for your sanity!!. And don't underestimate the support side of this . When you sell products you are the support desk aswell for the life of them!!!

My personal choice would also be to base the design from 11b (as thats where i believe all the good games are) and either leave unpopulated, or make changes from there for the other revisions. Thus leaving 11b with no daughter card needs!

Great project though

Make Stern Whitestar boards !

Been looking for one for two years.

I would love to redraw this one and offer replacements. Just reality is there is only a certain amount of time in each day and support, restock of current boards , shipping, admin, original board repairs etc takes up all the time.

The thought of off loading the assembly and distribution task to @Paul like the system 11 boards is very appealing!

RottenDog have redesigned in their latest releases, and we all know how reliable they were/areOne of the problems with copying an original system 11 design is you build in all the issues. I can see some changes, but it looks like they are using the original driver logic, which will burn just like an original if there is a fault. and take out the transistors and 74 logic! Why not use mosfet designs here that are well tested these days.

Also paul, are you assembling these yourself or getting a company to do it? I hope the latter for your sanity!!. And don't underestimate the support side of this . When you sell products you are the support desk aswell for the life of them!!!

My personal choice would also be to base the design from 11b (as thats where i believe all the good games are) and either leave unpopulated, or make changes from there for the other revisions. Thus leaving 11b with no daughter card needs!

Great project though

They now dont really resemble the originals at all, short of board sizes. And that brings a new set of problems and issues in itself.

They now dont really resemble the originals at all, short of board sizes. And that brings a new set of problems and issues in itself.They do serve a purpose i guess.... especially if there is no alternative.

Drive does use transistors, however the last stage I can choose between standard BJT or MOSFET (IRF9530/IRF9Z34N/FQP17P06). I'll be building using Mosfet . Yes it uses 74 logic and transistors, however why replace tried and tested? Generally speaking these boards are designed to be as close as possible to the Originals - thats the point - so that in 40+ years when I'm no longer about, people can still fix them based upon original designs, rather than trying to scratch about the net to find cct diagrams.

Yes, assembly is by myself. 100% UK Built & Tested. Would I oursource it commercially - probably - however as i dont have the designs and dont control the PCB origins, I cant get someone to produce and populate. That would be the ideal end goal, but just not there yet (or any time soon).

Completely aware of the support - this will be able to be done directly with myself with backup from Victor initially on anything i may not have seen. It's still a learning curve, however the boards arent THAT complex in themsevles.

I guess where i am coming from here is that these are bespoke boards - i.e. assembled at that time for a specific purpose to provide a solution for those that need it. As time goes on (maybe 6 months, maybe a year) then i will have a small stock on hand to ship immediately, however i need to get a feel for demand, and am trying to size myself accordingly. Which means initially it will be built to order with a lead time of around 3-4 weeks. As i have said before, they wont be the same price of the RD boards (and wont come with associated issues!). Any known of major issues have been redesigned. For Sys 11 as an example, the addition of the One shot piggy-back board (either plugin or externally) is an important add-on to extend the life of the machines, and prevent lots of crispy drive transistors! The ability to provide this as an external add-on to existing boards as well is a massive bonus, preserving existing boards.

This isnt just about just making boards to replace those which are faulty. It's about reproducing something that will outlast the remaining machines that are out there - much like the wonderful solutions that you provide. Thats the idea - not just a quick fix.

Its not just about sys11 though. Some very nice WPC89 and WPC95 boards, along with drop-in replacements for the WPC95 AV boards finally!! I've not gone for anything Sys 3-9 at this time, since i know little about those, and to be fair, there is much more demand on the sys11 and WPC stuff. The advantage is that should someone express an interest in say sys7 then it can be done.

RottenDog have redesigned in their latest releases, and we all know how reliable they were/areThey now dont really resemble the originals at all, short of board sizes. And that brings a new set of problems and issues in itself.

They do serve a purpose i guess.... especially if there is no alternative.

Drive does use transistors, however the last stage I can choose between standard BJT or MOSFET (IRF9530/IRF9Z34N/FQP17P06). I'll be building using Mosfet . Yes it uses 74 logic and transistors, however why replace tried and tested? Generally speaking these boards are designed to be as close as possible to the Originals - thats the point - so that in 40+ years when I'm no longer about, people can still fix them based upon original designs, rather than trying to scratch about the net to find cct diagrams.

Yes, assembly is by myself. 100% UK Built & Tested. Would I oursource it commercially - probably - however as i dont have the designs and dont control the PCB origins, I cant get someone to produce and populate. That would be the ideal end goal, but just not there yet (or any time soon).

Completely aware of the support - this will be able to be done directly with myself with backup from Victor initially on anything i may not have seen. It's still a learning curve, however the boards arent THAT complex in themsevles.

I guess where i am coming from here is that these are bespoke boards - i.e. assembled at that time for a specific purpose to provide a solution for those that need it. As time goes on (maybe 6 months, maybe a year) then i will have a small stock on hand to ship immediately, however i need to get a feel for demand, and am trying to size myself accordingly. Which means initially it will be built to order with a lead time of around 3-4 weeks. As i have said before, they wont be the same price of the RD boards (and wont come with associated issues!). Any known of major issues have been redesigned. For Sys 11 as an example, the addition of the One shot piggy-back board (either plugin or externally) is an important add-on to extend the life of the machines, and prevent lots of crispy drive transistors! The ability to provide this as an external add-on to existing boards as well is a massive bonus, preserving existing boards.

This isnt just about just making boards to replace those which are faulty. It's about reproducing something that will outlast the remaining machines that are out there - much like the wonderful solutions that you provide. Thats the idea - not just a quick fix.

Its not just about sys11 though. Some very nice WPC89 and WPC95 boards, along with drop-in replacements for the WPC95 AV boards finally!! I've not gone for anything Sys 3-9 at this time, since i know little about those, and to be fair, there is much more demand on the sys11 and WPC stuff. The advantage is that should someone express an interest in say sys7 then it can be done.

Wasn't meant as a negative at all, sorry if it came across like that. I fully support all new board avenues that come to life as i hope everyone knows. Just be aware of your support needs is all. Plus rottendog issues are not mosfet related really but thats another discussion.

Hats off to you for assembling them all by hand. I've spent years doing that, but i try to outsource as much as i can now as it gets seriously boring after you've done 100/200 etc of the same thing!

If you want some info on good places for assembly in the uk let me know, ie gather the parts yourself then ship in one go for assembly. Also you need some serious organised storage for those board parts. Racking and draws etc aint cheap either.

Last edited:

Certainly wasn't taken as a negative Jim! I'm all too aware that people see me as a newcomer, when realistically I've been qualified for over 30 years (OND in Electronics telecoms and computing) - Just only ever did stuff as a hobby for myself, and not for anyone else!Wasn't meant as a negative at all, sorry if it came across like that.

All have to start somewhere - Just being sure that i dont overstep what i'm capable of. Starting slowlyHats off to you for assembling them all by hand. I've spent years doing that, but i try to outsource as much as i can now as it gets seriously boring after you've done 100/200 etc of the same thing!

Yes please! Will drop you a PM!If you want some info on good places for assembly in the uk let me know, ie gather the parts yourself then ship in one go for assembly.

Already sorted. Currently ordering as-needed (Pre-built BOMs created by myself), however i have already identified multiple common components, and have started to stock pile those.... example would be 103z caps which are used by the hundredsAlso you need some serious organised storage for those board parts. Racking and draws etc aint cheap either.

Certainly wasn't taken as a negative Jim! I'm all too aware that people see me as a newcomer, when realistically I've been qualified for over 30 years (OND in Electronics telecoms and computing) - Just only ever did stuff as a hobby for myself, and not for anyone else!

All have to start somewhere - Just being sure that i dont overstep what i'm capable of. Starting slowly

Yes please! Will drop you a PM!

Already sorted. Currently ordering as-needed (Pre-built BOMs created by myself), however i have already identified multiple common components, and have started to stock pile those.... example would be 103z caps which are used by the hundreds

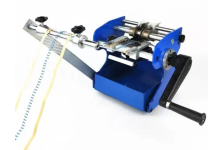

Storage wise, and maybe more useful once you have a few boards of parts to store, but this is what i built up years ago . Designed by my wife who likes to organise haha, i was stuck for awhile (and dying under a sea of cardboard boxes) until she came up with this idea, using ikea cabinet drawers and units

also pinball parts /larger items wise (power caps, heatsinks etc ), these boxes and shelving are always good

Update here!!! : https://www.pinballinfo.com/community/threads/new-replacement-boards-now-available.59349/

Therefore will close this thread. Many thanks to all that have ask questions and supported!

Therefore will close this thread. Many thanks to all that have ask questions and supported!

- Status

- Not open for further replies.