I took delivery of my first real Pinball machine yesterday.

Matt was totally up-front with me about the condition when I bought it, but even so i'm really happy with the purchase and I feel i've picked up a bargain. The table (a Data East Adventures of Rocky & Bullwinkle) is great fun to play and is in pretty good condition.

The cabinet is pretty beat up and as Matt put it "appears to have been attacked by a shark". But it's nothing I can't repair with the right materials and a little patience. The first challenge when it arrived was getting it in the house. It turns out the head was marginally too wide to get through the front door and it was just millimeters too wide for the back door as well. I could have probably got it in had I removed the door from it's hinges but then i'd probably have struggled moving the thing through the kitchen in one piece.

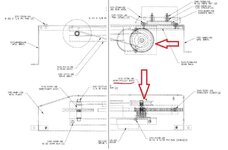

So ultimately I took the brave (or possibly stupid) move of stripping the head off. I took plenty of photos and then removed all of the connections from the PCB's. Stripped the head and transported both parts into the back room. And then this morning i've reconnected everything using my photos as reference. And amazingly it's all working.

Playfield is in great condition except from some slight wear around Aesops Hole (fnarr). Think first order will be to get a cliffy protector in place for the locations that need them (think there's 2 on this table). The ramp plastics are in great shape with no cracks or damage so i'm pleased about that too.

So far the list of things I need to look at are:

1. Trigger test shows a fault on the top center lane. So that needs investigating.

2. Lion plastic in the top hat is held together with tape. This is causing it to stick in the up position. The Rocky plastic behind it looks fine but that's also sticking so it's probably worth me removing the Lion first and see if the tape on that is also jamming the Rocky. Locating a Lion plastic could be fun - it appears Marco's list them but they're out of stock (and I suspect they'll remain that way).

3. Cliffy protectors

I'm sure i'll find plenty more to look at as time progresses.

Family are round for lunch later so i'm going to let the grandkids loose on it. The missus has already commented about how noisy it sounds from upstairs so i've dropped the volume a little for the moment. If it becomes a real issue then she'll have to invest in a Shack in the garden for me. ;-)

Matt was totally up-front with me about the condition when I bought it, but even so i'm really happy with the purchase and I feel i've picked up a bargain. The table (a Data East Adventures of Rocky & Bullwinkle) is great fun to play and is in pretty good condition.

The cabinet is pretty beat up and as Matt put it "appears to have been attacked by a shark". But it's nothing I can't repair with the right materials and a little patience. The first challenge when it arrived was getting it in the house. It turns out the head was marginally too wide to get through the front door and it was just millimeters too wide for the back door as well. I could have probably got it in had I removed the door from it's hinges but then i'd probably have struggled moving the thing through the kitchen in one piece.

So ultimately I took the brave (or possibly stupid) move of stripping the head off. I took plenty of photos and then removed all of the connections from the PCB's. Stripped the head and transported both parts into the back room. And then this morning i've reconnected everything using my photos as reference. And amazingly it's all working.

Playfield is in great condition except from some slight wear around Aesops Hole (fnarr). Think first order will be to get a cliffy protector in place for the locations that need them (think there's 2 on this table). The ramp plastics are in great shape with no cracks or damage so i'm pleased about that too.

So far the list of things I need to look at are:

1. Trigger test shows a fault on the top center lane. So that needs investigating.

2. Lion plastic in the top hat is held together with tape. This is causing it to stick in the up position. The Rocky plastic behind it looks fine but that's also sticking so it's probably worth me removing the Lion first and see if the tape on that is also jamming the Rocky. Locating a Lion plastic could be fun - it appears Marco's list them but they're out of stock (and I suspect they'll remain that way).

3. Cliffy protectors

I'm sure i'll find plenty more to look at as time progresses.

Family are round for lunch later so i'm going to let the grandkids loose on it. The missus has already commented about how noisy it sounds from upstairs so i've dropped the volume a little for the moment. If it becomes a real issue then she'll have to invest in a Shack in the garden for me. ;-)