next step is im trying to learn myself to make some coding to control the solenoids and sensors.

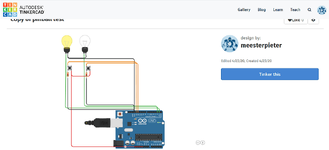

after quite some fiddeling i found out that there's a decent arduino simulator on the web ; tinkercad

for those interested, here is a link to one of my concepts:

https://www.tinkercad.com/things/3Z0Opq2tRS4

that's been quite an improvement, especially since im just starting on this stuff. makes it much easier and faster to test a circuit and coding.

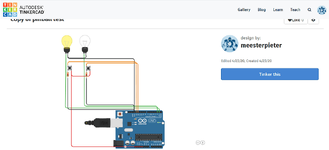

also learned that the basic stuff isn't going to cut it, since working with these heavy solenoids can lead to some easy coil burning.

after analysing the original DE schematics, i found that the flippers work on different voltages, around 48v and 20v i believe. this to prevent the coil from burning when you keep pressing the flipper.

I've thought up 2 ways to cover that in my setup, first i need to program the arduino so that i can switch from 1 power source to another after a certain length of time, and second i want to implement a fail safe in case my program is buggy. that would be with a programmable timer switch.

for switching the solenoids with the arduino i will be using a separate 5v power source, a mosfet driver and a timer board

driving the solenoids will be a +-40v power source, for testing purposes i made a simple setup without the arduino and with an old train transformer for a lower voltage

the 5v power source will also be used to power all the lighting and such as that also runs on 5v

here's my first simple test with a 5v switch, that uses a mosfet driver to switch on the higher (+-12v) voltage

After putting the bottom assemblies on my playfield im already noticing it is getting heavier and bulkier to work with without damaging stuff.

So i guess i'll need a playfield tipper a bit sooner than i expected!

I wanted a lightweight demountable tipper, since i only have a very limited amount of workspace, and i expect the project to be shelved for at least several weeks every now and then.

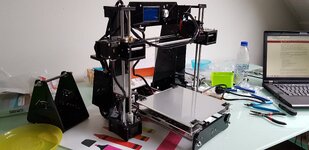

I've seen a lot of sturdy 3d printers made with aluminium extruded frames, which are easy to build yourself

after checking the weight it should be able to handle, i decided to build a tipper from 2020 aluminium profiles

the only thing i couldn't really find for an affordable price was a pivoting housing that i could easily screw down at different angles.

so i designed that in 3d and printed it. its not really state of the art, but it works fine for now

made a rotating mechanism with my 3d printer