I'll use this post as a log for a new side project; I'll be taking a mould from an original Judge Dredd Topper for producing a copy in resin. This will be a more robust form, I can't believe how thin the original is I suspect most example out there are damaged to some degree.

I'll be trying out different metal powders to produce finish that can be buffed up to a high polish as well as a rattle can metallic finish.

So far I've made a mould of one of the claws and produced a master copy, this will be prepared with registration keys for mating up with the main body and a new rubber skin made.

Next up I'll be making a fibreglass two piece case for the main body which will allow a thin rubber skin to be poured.

I'll be trying out different metal powders to produce finish that can be buffed up to a high polish as well as a rattle can metallic finish.

So far I've made a mould of one of the claws and produced a master copy, this will be prepared with registration keys for mating up with the main body and a new rubber skin made.

Next up I'll be making a fibreglass two piece case for the main body which will allow a thin rubber skin to be poured.

Attachments

-

unbox.jpg149.9 KB · Views: 99

unbox.jpg149.9 KB · Views: 99 -

legs-off.jpg133.3 KB · Views: 92

legs-off.jpg133.3 KB · Views: 92 -

materials.jpg158.4 KB · Views: 87

materials.jpg158.4 KB · Views: 87 -

clay-skin.jpg100.8 KB · Views: 76

clay-skin.jpg100.8 KB · Views: 76 -

prep-plaster.jpg94.8 KB · Views: 73

prep-plaster.jpg94.8 KB · Views: 73 -

demould-clay.jpg75.9 KB · Views: 70

demould-clay.jpg75.9 KB · Views: 70 -

pour-rubber.jpg144.8 KB · Views: 73

pour-rubber.jpg144.8 KB · Views: 73 -

rubber-skin.jpg87.4 KB · Views: 80

rubber-skin.jpg87.4 KB · Views: 80 -

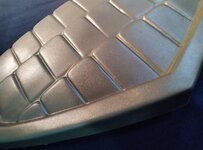

master-copy.jpg65.2 KB · Views: 104

master-copy.jpg65.2 KB · Views: 104