biglouieuk

Site Supporter

evening all.

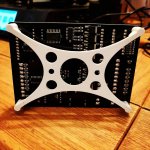

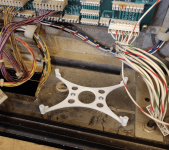

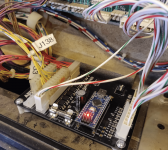

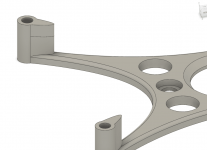

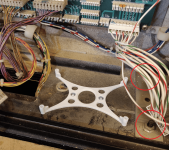

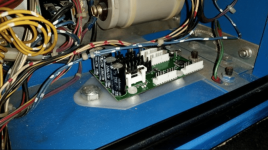

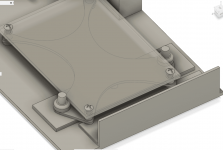

Picked up an Afterglow board from a forum member, just installed, what a wonderful thing!

First thing, I am trying to connect via USB to look at config. I get a failed to connect on COM3. Wondered if anyone else had successfully connected or had as link to any troubleshooting?

Second thing was the 18v supply. It would feel better to me if it wasn't pinned to the 18v TP. Anyone successfully run 18v from anywhere else at all? I'm not sure there is 18v anywhere else other than out of the transformer perhaps?

The glow is goooooood. Love this little board already...

Love this little board already...

Picked up an Afterglow board from a forum member, just installed, what a wonderful thing!

First thing, I am trying to connect via USB to look at config. I get a failed to connect on COM3. Wondered if anyone else had successfully connected or had as link to any troubleshooting?

Second thing was the 18v supply. It would feel better to me if it wasn't pinned to the 18v TP. Anyone successfully run 18v from anywhere else at all? I'm not sure there is 18v anywhere else other than out of the transformer perhaps?

The glow is goooooood.